AEP alum creates a gravity-off switch in orbit

by Diane Tessaglia-Hymes, photos courtesy of Varda Space Industries

There’s a new star in the aerospace industry and it’s bringing a gravity-off switch to manufacturing. Varda Space Industries, co-founded and led by an AEP alum, is sending satellites to space, where products used on Earth can be created in a zero-gravity, dust-free environment.

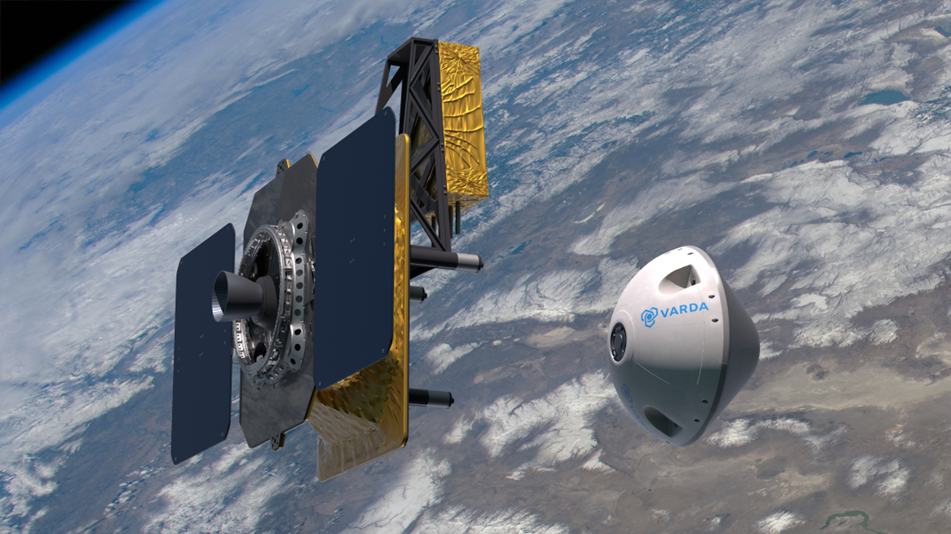

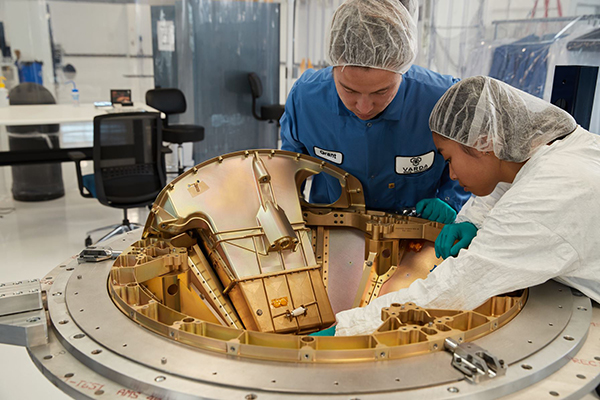

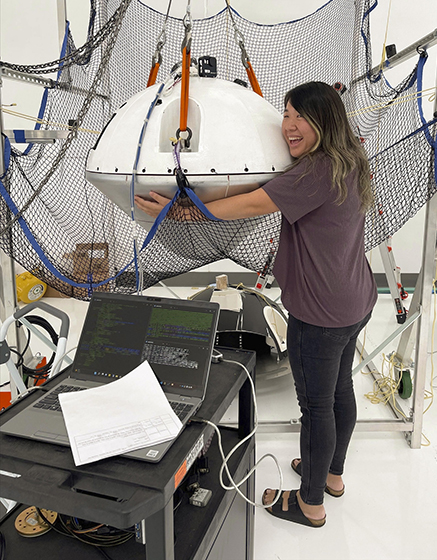

“We’re a microgravity platform for any type of manufacturing,” explains Will Bruey ’11, M.Eng. ’12, CEO of Varda Space Industries, a company he founded in 2020 with Delian Asparouhov. Space manufacturing has been around for decades, dating back to 1969 when Russian cosmonauts determined that the environment of space “may solve many welding problems.” Starting in the 1970s, space manufacturing took the form of experimental attempts done primarily at Skylab2, and later at Spacelab and the International Space Station. Only recently has the cost to go to space fallen to a point where it can now be economical to commercially produce some products in space. This is in part due to reusable rockets that have lowered the cost of access to space and opened up a range of in-space activities. “After our satellites separate from the rocket, they perform operations such as mixing or heating chemicals,” Bruey explains, “and then, after those operations are complete, we do a deorbit burn to send small capsules back to Earth with the materials produced. Our capsules—about 1 meter in diameter—survive re-entry, deploy parachutes, and land with the manufactured contents that we then deliver to our customers.

MAKING MATERIALS IN MICROGRAVITY

One such set of products serves the pharmaceutical industry: drugs formulated using microgravity. “The ideal application for our capsules is manufacturing high-value chemicals in space,” says Bruey. “There are a lot of things we can do in space to create value for chemists on Earth, for example, drug molecules crystallize differently in microgravity than they do here on Earth. This can improve parameters of high interest, such as solubility. The reason we manufacture in space is because of the unique way microgravity influences chemistry.” Crystal growth behavior—both morphology and growth rate—are different in microgravity than an equivalent setup experiencing the Earth’s gravity. This is partly because as crystals grow they release heat, and that heat causes convective currents in the solution. A growing crystal that sinks due to its own weight would also create convective currents from its sinking motion. In microgravity, there is less of this convective transport. As a result, crystals grow differently, creating different geometric lattice shapes as their molecules fit and stack together in a repeating sequence. This can also create unique ratios between their morphologies as well. “This is important because the morphology of a crystal defines many of its macroscopic properties,” Bruey says. “In the pharmaceutical world, solubility, or how fast the drug dissolves in the body, is a particularly important property. Space manufacturing in microgravity allows us to alter the outcome of crystal growth to influence properties like solubility.”

But the applications don’t stop at medicine. The International Space Station has hosted countless experiments using the unique environment of microgravity to produce unique results. Things like fiber optics, silicon wafers, and special metal alloys all have unique benefits from being fabricated in microgravity. And since gravity is a fundamental force of physics, Varda’s platform can be useful across all disciplines of engineering—just like an AEP degree.

AN INDUSTRIAL PARK IN SPACE

In the long term, Bruey wants Varda to build the first off-planet industrial park at-scale. Now that rockets are reusable and the costs have dropped accordingly, there are no significant technical or economic barriers to this goal. “We’re not really a typical aerospace company,” he says, “because our customers don’t care that we’re going to space. They only care that we can turn off gravity for them.” For Varda, that means manufacturing mostly small things like expensive chemicals or small products in the short-term as the space industry continues to grow. But as launch costs continue to drop, Bruey hopes to scale up both the range of products Varda creates as well as the size of each. Right now, the telecom and remote sensing industries are the primary users of space commercially. Varda wants to be at the forefront of the next innovation, which they’re predicting will be the first off-planet industrial park. Bruey envisions a distributed industrial park, rather than a single large “station.” Bruey envisions a set of robotic production satellites orbiting Earth, with each satellite creating a different product: drug molecules, fiber optics, etcetera.

“We can bring the raw materials to those production satellites with our Varda spacecraft, and bring back finished products with our reentry capsules.” Bruey adds: “It’s hard to say what’s next in any industry, because it’s all speculation, but I think what we can say about Varda’s future is that it has a very real chance of benefiting people on Earth in ways that simply can’t be done any other way. If successful, we’ll end up inciting a positive feedback loop to drive human activity in space.” By manufacturing those first few products, Bruey hopes he can drive demand for launches, setting that positive feedback loop in motion to decrease launch costs and increase the economical products Varda can offer.

AEP PROVIDES PATHS TO AEROSPACE AND OTHER FIELDS TO ALUMNI

Varda Space Industries, which has so far garnered more than $53 million in start-up capital, has approximately 50 employees and 20 interns, including AEP undergrads Nick Thomas ‘23 and Sam Noles ’23 (see page 12). One of the company’s directors is AEP alum Wendy Shimata ’09. After Cornell, Shimata worked at Boeing in the guidance, navigation, and controls department for about seven years, and then accepted a job at SpaceX in the software department, eventually leading the Dragon Software team. That’s where she met Bruey, and the two worked together in mission control. After founding Varda, Bruey reached out to his fellow AEP alum to bring her on the team. Both Bruey and Shimata credit AEP with giving them the skills needed to be successful, and teaching them how to narrow in on the specific problem they are facing and how to solve it. For Shimata, AEP provided a “really good fundamental basis of how everything works.” One feature of AEP that drew her to Cornell was that it not only provided her with a solid grounding in the foundations of engineering principles, it also gave her the opportunity to apply her knowledge through project teams at Cornell.

“AEP prepared me really well for all my positions: Boeing, and SpaceX, and Varda” she says. “It enabled me to approach challenges in a fundamentals-first sort of way, and by doing so, allowed me to solve new and innovative problems. For example, I might not know this subject specifically or that equation specifically, but I have a solid understanding of the underlying principals, and I know I can figure it out.”

As a child, Shimata was very interested in space and astronomy, and became interested in pushing the boundary of space applications and exploration. At Cornell, most of her electives were very space-oriented: control theory, aerospace, and GPS. She was part of Professor Mason Peck’s satellite engineering project team in the Sibley School of Mechanical and Aerospace Engineering for three years as an undergraduate student.

Bruey credits his AEP B.S. degree with helping him unlock the problem-solving part of his brain, while also preparing him to pursue a multitude of career paths.

“The role models for the AEP engineer are people like Schrodinger and the other physicists of the early 20th century—people who work on cutting-edge ideas. This is why I chose to be an engineer, and also why I chose to work at SpaceX. I thought it was the coolest, most cutting-edge engineering company that existed.” Most of Bruey’s undergraduate electives were in electrical engineering. That, combined with a strong fundamental physics background, plus working on Professor Mason Peck’s satellite team, gave Bruey enough preparation to contribute at SpaceX as an electrical engineer, and then later start his own company, Varda Space Industries.

“The question is, how can we be creative and innovative, because that’s what really drives our industry and pushes it to new heights,” he said. “AEP taught me to think about and understand almost any engineering problem, and it gave me a great toolbox of skills to do exactly that in my career.” ♦